HOW LONG DOES PPE LAST? (PROBABLY NOT AS LONG AS YOU THINK)

5 minute read

The Personal Protective Equipment (PPE) at Work Regulations 1992 place duties on employers to ensure that PPE is:

- Properly assessed before use to make sure it is fit for purpose.

- Maintained and stored properly.

- Provided with instructions on how to use it safely.

- Used correctly by workers.

But are you aware that PPE also comes with an expiration date?

Whether you're in healthcare, construction, or anyone exposed to potential risks, PPE is your fifth line of defence in the hierarchy of controls. But like most material things, PPE doesn’t last forever and wearing poorly preserved or malfunctioning equipment, could be just as dangerous as not wearing any form of protection at all.

Ideally, work boots should last 6-12 months on the job; hard hats and ear defenders should last up to 3 years in their original packaging and up to 3 years in the workplace and in general, you can expect high-visibility clothing to last about six months with regular use - but really, it all depends on how the equipment is used, stored, and cared for.

In this blog, we share with you the key signs that it’s probably time to replace your PPE to ensure safety at all times.

THE IMPORTANCE OF UP-TO-DATE PPE

- Safety first: Outdated PPE can compromise your safety. Materials break down over time, reducing their effectiveness in shielding you from hazards. Helmets, gloves, masks, and other forms of protection are not invincible, and they degrade with use and age.

- Legal compliance: All industries are subject to strict regulations regarding PPE usage and it is the duty of the employer to provide the appropriate PPE for the task when required. Outdated or improperly maintained equipment can lead to compliance issues, fines, and even legal troubles.

- Health and wellbeing: Wearing outdated PPE can have health consequences. For example, expired respirator filters may not filter out harmful particles effectively, exposing you to respiratory risks. Similarly, expired safety goggles or face shields may have scratched lenses or weakened frames, reducing their ability to shield the eyes from impact or chemical splashes.

HOW TO CHECK THE EXPIRY DATE

Here’s how to check the expiry date of your PPE:

Just because a hard hat has a 3-year lifespan, it does not mean it will last you for 3 years. It's a common misconception that you can use your hard hat until it expires, but as we have seen from the manufacturer's guidance, it's not always the case. The expiration date is the maximum lifespan, not the date for replacement.

The General rule of thumb for replacement:

- Read the labels: Start by examining the labels and tags on your gear. Manufacturers often include expiration dates or recommended service life. If you can't find this information, contact the manufacturer, or refer to user manuals.

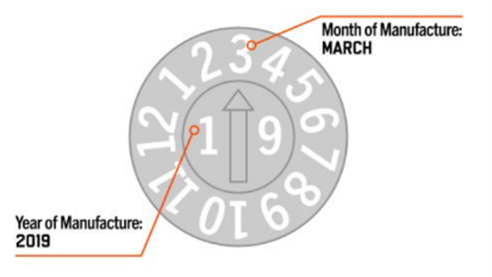

Hard hats should have the ‘manufactured on’ date stamped inside. You can use this as a guide for the point at which your 3-5 years has begun. So, although you might have only been wearing it for 3 years, the storage time prior to this will contribute to the deterioration of the material.

- Visual inspection: Look for signs of wear and tear. Cracks, tears, or discoloration may indicate that the equipment is past its prime.

- Shelf life: Understand that different PPE items have different shelf lives. Be aware of the specific guidelines for each type of equipment.

- Store properly: Proper storage can extend the life of your PPE. Keep it in a cool, dry place away from direct sunlight and chemicals that could degrade the materials.

PPE MAINTENANCE TIPS

Keeping PPE is up to date doesn't end with checking expiry dates. Here are some maintenance tips to ensure your equipment remains reliable:

- Regular inspection: Employers should have an annual plan in place to inspect all PPE and routinely check PPE for damage or signs of wear. Any damaged items should be replaced promptly.

- Cleaning: Clean your PPE according to manufacturer recommendations. For example, washing instructions for hi-vis may differ from those for gloves.

- Proper storage: Store your PPE correctly when not in use. Helmets should be kept on a flat surface, while respirators may require a sealed container to prevent contamination.

- Record keeping: Maintain records of inspections and replacements. This documentation can be invaluable for compliance purposes and ensuring the timely replacement of gear.

- Training: Ensure that employees and users are educated on the importance of keeping PPE up to date and the proper procedures for checking and maintaining it.

It is important to be aware of the hazards caused by incorrectly wearing your PPE and by ensuring these steps, you're not only safeguarding your own well-being but also upholding safety standards and legal requirements in your industry. Remember, PPE is more than just equipment; it's your lifeline to safety.

Are you in need of replacing your old PPE? Shop our extensive range today >